LFD BEARINGS

IN CONTROLLABLE ROLLERS

PLUG AND PLAY – DRIVE ROLLER SOLUTIONS

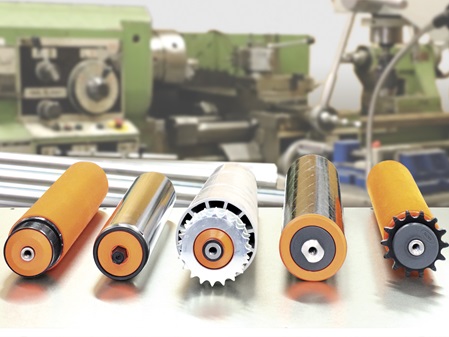

A mere three years ago, NDW began the development of drive rollers solutions to simplify the use of motor rollers and to make the control of a complete conveyor system more inexpensive and easier. The LFD Group delivered the special EMQ bearings for this, which are used due to the particularly effective minimisation of friction losses in the controllable rollers of various types.

As a result of the development work, the innovative company brought the first four self-developed drive control units to the market in 2018. This product line (Budget, Basic, Basic+ 24V and Basic+ 230V) can be used both for simple conveyor systems as well as for the control of more complex systems. In this regard, the Basic+ 230V controller is the only one available on the market that can be operated without a transformer and as a result can control and drive up to 20 individual motors without a new power supply.

New technology has been established

As a result of the combination of a powerful, brushless motor roller (50DRX and 60DRX), NDW has established a new technology, which is excellently suited for the handling of light to medium-heavy products with a weight of up to 300 kg.

In close partnership with floWlogitech Förderelemente GmbH based in Marienmünster, not only are different durable load-bearing rollers and drums manufactured in the own production and the high-quality LFD bearings are cleanly pressed in, but currently a new production plant NDW Germany is being planned. This will begin production in 2019 at the Marienmünster location and will take over the current load-bearing roller production of the floWlogitech company.

Investments in digital innovations

Wireless configuration of the systems

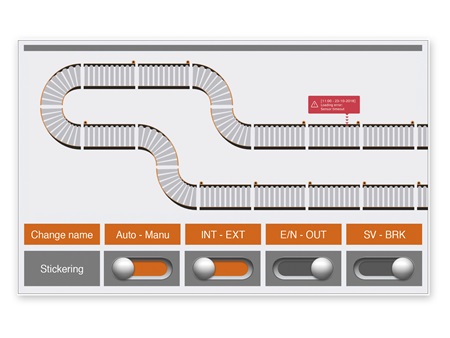

The partnership establishes new possibilities in the area of the control of conveyor systems. The products are ideal for plug-and-play solutions and have the ability of communicating bi-directionally with each other. A major advantage is the use of the integrated power supply (Basic+ 230V). This negates the need for using a transformer. The control which has been developed completely in-house enables with the use of a PLC to accumulate the motor rollers and combine them as desired. Furthermore, the utilised software can be expanded and adapted without difficulty to the control of additional system technology.

An additional major advantage is the wireless configurability of the drive regulators (Basic, Basic+ 24V, Basic+ 230V) with the NDW Connect App. Due to the IP67 rating of the controller (Basic+ 24V, Basic+ 230V) and the removal of the transformer (Basic+ 230V), the new solutions are also excellently suited for the use in the food industry.

Precision work with EMQ deep groove ball bearings

The NDW motor rollers have been designed for different applications. For this reason, the motor roller is available both in a variant made of galvanised steel as well as in stainless steel and furthermore in the diameters of ø 50 mm and ø 60 mm. The protection classes are IP21 (Budget), IP54 (Basic) and IP67 (Basic+ 24V, Basic+ 230V).

The motors are available with the EMQ deep groove ball bearings by LFD in three speed levels: 17, 30 and 60 m/min. The motor rollers can be fitted with a rubber, PU or PVC coating. The rollers are equipped with conical plastic elements for bend applications.

A continuous further development of the motors and electronic components safeguards the future sustainability in the sector of conveyor technology.

A complex system control

INDUSTRY 4.0 and NDW Connect

NDW Connect is a new intelligent technology that integrates the conveyor systems in the cloud and enables global support, service and monitoring for everyone and makes it affordable. A dedicated app provides extensive insight in the efficiency of the respective conveyor system. The entire control process is performed in the own WLAN network and in this manner enables global remote maintenance and monitoring.

As a next step in the direction of Industry 4.0, in the near future is will be possible to digitally evaluate operational information such as service life, operating temperature and drive load.