GET racing –

The roll-out of the FS218

GET racing is the student racing team of the Technical University of Dortmund and the contact point for all petrol heads. Every year, the team constructs a single seater racing car, which is driven at various Formula Student events in Europe.

A multitude of members plan, construct and manufacture the racing car under their own direction and in the course of this experiences the development process of a dream. With more than 30 members from various faculties and study programmes, GET racing does not only create new things, but also shares team-building joint activities outside of the workshops during their leisure time.

In 2018, the team is comprised of more than 30 students, who are mainly enrolled in engineering sciences such mechanical engineering or electrical engineering. But many economists and students from other faculties in the meanwhile are now also part of the team.

LFD is a gold sponsor

As a gold sponsor, LFD is a consultant of the GET racing team and closely works together with the development team. The established bearing manufacturer from Dortmund is renowned for ball and antifriction bearings of the highest quality as well as the in-house manufacture according to German standards. This demand is safeguarded by in-house, ISO-certified production lines, the most modern laboratory technology as well as several in-house inspection and testing benches, as a result of which new developments and optimizations of applications can be implemented in a flexible manner..

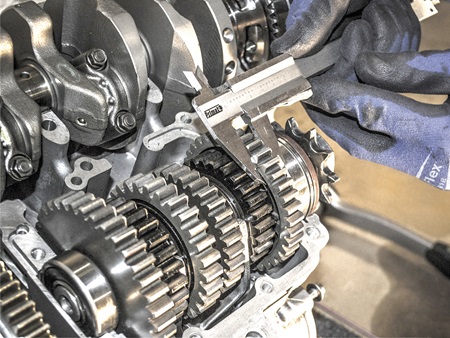

A multitude of areas of application

LFD bearings are installed throughout the entire vehicle. Irrespective whether in the drive train to the differential bearing, in the steering box on the pinion shaft or in the throttle valve. The suitable bearings are used for each specific application.

Special meaning for the chassis

Most of the bearings made available by LFD are installed in the chassis. Here, maintenance-free spherical plain bearings are used for the wheel suspension and must meet strict requirements. In particular, the topic of bearing play is a very important aspect as this is stipulated by the regulations and is verified by the technical inspection. The respective inspectors closely check the bearings and make sure that the racing car will be able to withstand all disciplines and in particular also long-distance races of 22 km. In the event that the spherical plain bearings or wheel bearings have a certain amount of play, then it is possible that it will not be approved for the dynamic disciplines.

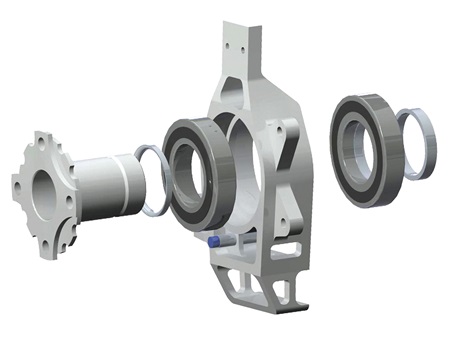

Wheel bearing is critical

An additional very important assembly unit is the wheel bearing as a rotating connection between the wheel hub and the hub carrier. Just as with the wheel suspension, no play may occur in these areas. At the same time, the requirements are even more specific here. The bearing must absorb high wheel loads and simultaneously be very small and light in order to reduce the unsprung mass. This is very important for the chassis and the overall handling properties of the vehicle. Using a wheel bearing developed in cooperation with LFD, the racing team has been able to tackle precisely this problem. LFD will continue to support the team following the successful roll-out of the new FS218.

Sharing of knowledge

In addition to bearings, LFD supports the GET racing team with a great deal of knowledge on the topic of antifriction bearings, which are obtained directly from this manufacturer. At several meetings, the calculations of the wheel bearings were verified and notes and proposals were made for a possible optimization. Topics such as the selection of the correct lubricant and its effect on the antifriction bearings as well as tolerances play an important part. This knowledge can then be presented by the students during their design presentations at the events.

Technical inspection

Before each event, the vehicle is subjected to a technical inspection. In the course of this so-called “scrutineering”, the construction of the racing car and all parts are checked for their conformity with the regulations. After scrutineering has been passed, the car is placed on the tilt table. Here, the vehicle is tilted by 45°, during which no liquids may run out. Thereupon, the vehicle is tilted to 60°, during which it may neither tip over nor may anything be released.

FORMULA STUDENT

With the new FS218, just like every year, participation in international competition has been planned. Thus, Formula Student is an international construction competition for students, which is strongly modelled on the American Formula SAE™.

The Formula SAE™ was started in 1981 by the Society of Automotive Engineers (SAE) in the USA as a university competition. Since then, there have been offshoots in twelve different countries. They mainly have very similar rules, enabling the teams to participate in several events with their vehicles.