Roller manufacture for conveyor lines

The Bauer Förderelemente company does not view itself in the sector of conveyor technology as an original equipment manufacturer, but rather customers seek out the company when they experience difficulties with mass-produced goods. The core business lies in the provision of spare parts and fabrication of special installations.

The rollers are used in the quarrying of stone and the further processing, recycling, the breaking up of the material, crushing, shredding as well as general conveyor technology, but also used in many other production sequences.

Large market in Norway

In Norway, the reasons for the high demand for conveyor elements lies in the lack of infrastructure in regard to the road network. In principle, there is also no necessity to develop uninhabited areas at great expense. It is less expensive to work with conveyor lines for the removal of raw materials. Frequently, the quarry is connected directly from the mountains via conveyor belts with a removed fjord. The loading and shipping is performed from there. Rollers made by Bauer are a sought-after product for such systems.

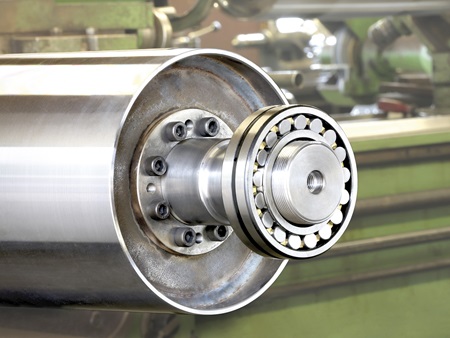

Stable roller construction

What other suppliers already view as a special production or heavy-duty roller, is considered as a standard conveyor element by Bauer: Among others, a higher wall thickness starting from 2.9 mm and an installed stronger bottom as a deep-drawing part. The difference can be shown best when an inexpensive component and a roller from the manufacturer of the Bauer company are cut open, in which the difference in the construction becomes clearly evident. However, the mere comparison in weight shows clearly that this rollers are of a higher quality.

A large fleet of machinery supports the precise manufacture with turret lathes, automatic welders, conventional lathes, horizontal and vertical milling machines, additionally hydraulic presses, enabling the required bearings to be pressed in with a certain preload and to prevent the outer ring from turning later on in the product. These presses deliver an impressive pressure of up to 6 t.

LFD spherical roller bearings are a leap in quality

In regard to the purchased components of insert roller bearings, ball bearings or spherical roller bearings, LFD Wälzlager GmbH is active as a supplier of high quality bearings. “For large rollers, there of course is a leap in quality when spherical roller bearings are used instead of ball bearings,” Manuel Bauer explains during the interview. Beforehand, of course repeated exact examinations of the requirements and the cost-benefit factor are performed.

Nevertheless, in regard to pillow block or flange bearings, when it is possible in price, Manuel Bauer recommends installing LFD spherical roller bearings with clamping sleeves. Because these are able to absorb possible deflections. Additionally, the force absorption can be distributed better due to a significantly more durable support point.

Standard and

special carrier rollers

Reliable radial load capacity

When more inexpensive ball bearings are used in lieu of spherical roller bearings, it should always be examined precisely whether the installed ball bearings are suitable in regard to design, performance and load in the respective application. As is known, different bearings fit in the different housings.

Proper design of the conveyor systems

For example, when the bearings of a customer who works with more inexpensive rollers made overseas experiences a roller failure, then usually the bearings are not the weak point. The conveyor system is simply designed incorrectly for the bearings. Because the rollers have a deflection capacity and the reliable radial load capacity is critical for the bearings.

LFD: own laboratory equipment and test benches

LFD ensures these requirements with its own laboratory equipment and test benches. Nevertheless, spherical roller bearings are more flexible than deep groove ball bearings. Therefore, a consensus must be reached on what the respective bearing must absorb and by which factor the axle may deflect.

In the overall production, then a very specific conveyor element is created, which is Made in Germany and is especially designed for sustainability.