BALL BEARINGS IN SORTING PLANTS

In modern sorting plants for online retail, articles in incomprehensible quantities for millions of active customers must be prepared for dispatch.

Likewise, returns and complaints must be handled. In so-called bag sorting systems, hundreds of thousands of small LFD ball bearings are in use, which reliably transport goods. In close cooperation with the customer, products modified by LFD are created, which are optimally suited for this use.

Development of warehouse automation technology

In October 2014, Smatec GmbH was acquired by Vanderlande. The German company (based in Bielefeld) has more than 30 years of experience in the development of warehouse automation technology and concepts. The know-how and expert knowledge of both the former Smatec owner and founder, Ralf Schneuing, as well as that of his experienced team have been secured.

Vanderlande bag sorting systems in use worldwide

It is the objective of large online portals for E-commerce to continue a profitable course of growth, gain market share and to strengthen the own competitive position. To achieve this, such E-commerce platforms rely on the technology by Vanderlande. With thousands of brands, hundreds of thousands of articles and millions of customers, the connection of brands, partners and customers in various countries is facilitated. To be closer to the customer in different regions and to keep delivery times short, new automated logistics centres are established continuously. As a long-time partner and market leader in the area of E-commerce, the system integrator Vanderlande, who is active worldwide, was tasked with the planning and implementation of new bag sorting systems.

Secure workflow

from loading to the packing station

Optimal start-up behaviour

For the LFD deep groove ball bearings to function smoothly and durably in such a system, it is mandatory that a stable film of lubricant is created between the race and the ball.

Generally such lubricating greases are comprised of approx. 80% of lubricating oil, approx. 5% to 10% of thickener and approx. 10% to 15% of additives. The thickener used in the most common types of ball bearing greases is lithium soap grease.

This forms a sponge-like framework that encloses the oil droplets. Whether a lubricant film can establish itself depends on the bearing construction, the rotation speed, however in particular on the viscosity of the lubricant. The viscosity ratio at operating temperature is used as the measure for the effectiveness of the lubrication.

It reflects the ratio of the actual kinematic viscosity to the viscosity, which is required for a sufficient lubrication. The viscosity (thickness) of a lubricant determines the thickness of the oil layer between metallic surfaces.

The greater the viscosity, the thicker (less flowable) the fluid is; the lower the viscosity, the thinner (more flowable) it is. Vanderlande installs LFD deep groove ball bearings with a lubricant with very low viscosity. As a result, the optimal start-up behaviour of the bags is ensured.

Heart of the order fulfilment system

The bag system is the heart of the order fulfilment system in the logistics centre. It is the AIRTRAX Pocket by Vanderlande, which was first presented on the LogiMAT trade fair. This powerful state-of-the-art unit among others impresses with future-oriented features:

Use of modern, proven materials, very low number of components as well as redundant technology/function. The bag sorting system AIRTRAX Pocket is part of the reliable and innovative AIRTRAX product line by Vanderlande, which in a highly frequent environment with large goods volumes efficiently transports, sorts, sequences and stores along larger distances and with changing heights.

Scalable and as a result highly flexible

The pocket system is scalable and as a result is highly flexible when handling quickly expanding and dynamic product portfolios, irrespective whether this is in regard to fashion (including hanging articles of clothing), jewellery, multimedia or other articles. The handling of returns has never been performed with this degree of efficiency, as the returned articles are processed immediately and made available automatically for new customers.

AIRTRAX is the first concept on the market with a one hundred percent friction drive and as a result, in comparison with traditional chain drives, runs without interruption and with little mechanical systems as well as control, even in the event of the bridging of larger distances.

For example, with the utilised plastic chain links, nothing must be tensioned, which facilitates larger maintenance intervals. These chains do not have to be oiled or greased, as a result unprotected goods are not soiled. In this manner, dealers and consumers receive clean goods as expected at a continuously high quality level, as no stains or other flaws can occur. Vanderlande sets standards with such exciting and future-oriented projects and successfully continues partnerships with large portals.

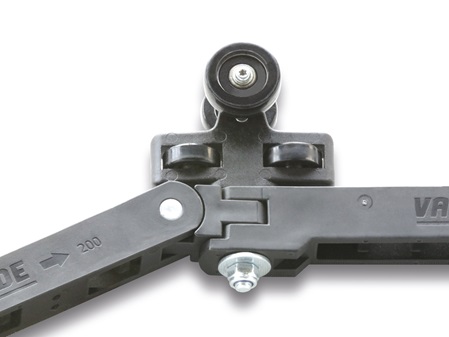

Bag systems

They are controlled via the RFID transponder of the roller adapter to which it is mounted. The bag itself is comprised of polyester fabric, which is reinforced with a plastic panel in the lower section. Special plastic frames provide an improved function during loading and unloading, reduce the volume level of the system and fulfil the following features: They preserve the form of the bags and at the dispatch and packing positions a large insertion opening is created by lifting the frame.

Simple and secure workflow from loading to the packing station – the operator at the loading station removes individual parts from the provided containers or boxes, moves them along the scanner with a movement of their hand and throws them in a shaft. Now the goods are in the bag, in each case only one part. From this point on, all further steps occur automatically, e.g. the buffering or the multi-stage sequence sorting.