DRIVE TECHNOLOGY AND GEAR MANUFACTURING

As a result of comprehensive knowledge and many years of experience in the field of drive technology, Wolfgang Schmahl GmbH & Co. KG ensures the production according to state-of-the-art technology and is one of the most innovative manufacturers of gears in Europe.

As a competent partner, the company supplies manufacturers of agricultural and road construction machinery, general machine and system construction as well as the sector of defence technology, marine transmissions, engine manufacturing and wind power.

On the basis of an impressive, flexible and modern fleet of machinery, SCHMAHL meets the expectations that are set to a competent supplier – whether for large components of up to 20 t or small-scale production. It is their objective to continue to invest in the most modern gear machining technology so in future they can continue to offer problem solutions and products at the highest technical level.

Flexible and modern

gear machining technology

Complete depth of production

As a specialist in regard to the manufacture of gear wheels and gearboxes, from the very start the company has relied on a collaborative dialogue. Its particular strength lies in the development and manufacture of special constructions and specific drive solutions with a complete depth of production. The highest degree of precision and quality during the manufacture of the individual components is ensured from the first cut to the finished part.

Dialogue and 3D simulation

A competent team of experienced engineers develops the optimal, individual solution for the respective customer. With the most advanced 3D simulation programs and gearing calculation software, development and parts costs can be reduced from the very first step. Industry-specific determinations are not made, but instead a strong focus is placed on special solutions, which are not offered in this technical and economical form by series manufacturers.

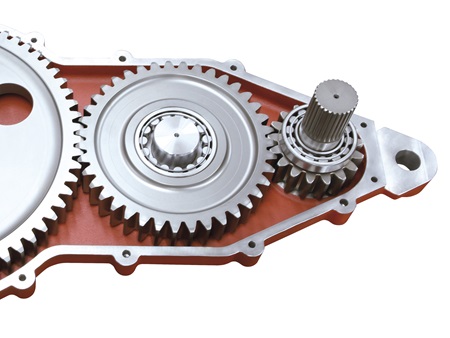

Gearing technology

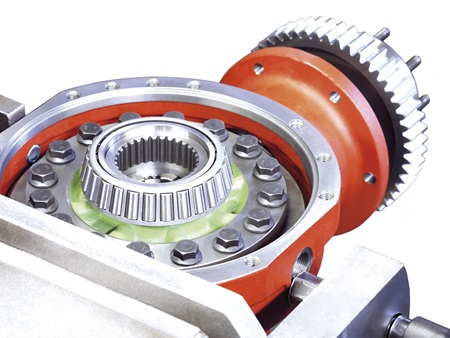

Perfect small and large-scale production and the assembly of complete gearboxes can be coordinated individually. The latest production machines, in conjunction with many years of experience in the field of gearing technology result in optimal solutions.

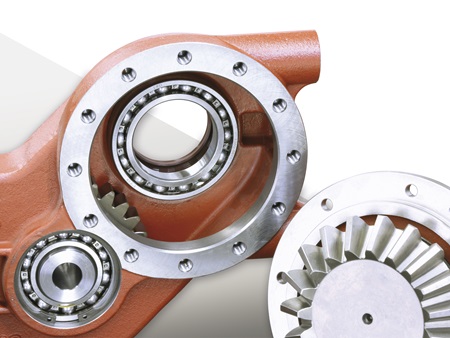

Loadable bearings

The precise fabrication competence of the SCHMAHL company in conjunction with the high quality of the utilised LFD bearings ensures a long service life of the gearboxes. Due to a comprehensive product range, LFD supplies EMQ deep groove ball bearings, spherical roller bearings, taper roller bearings and cylindrical roller bearings in different sizes for the various drives.

The foundation for the installed bearings is also provided by the especially high-grade bearing steel, of which the degree of purity is among others a guarantee for the high degree of utilisation, but also for the long service life. As a result, LFD bearings are extraordinarily loadable even under extremely tough conditions.

Perfect small and large-scale series production

Gear wheels:

Straight or helical cut, module 1.5 – 36 max. outer diameter up to 3,500 mm, tooth flank grinding up to quality DIN 3.

Spline shafts/knock-out spindles:

With almost all existing profile dimensions according to DIN and SAE.

Bevel gears:

Straight-cut with spherical tooth flanks, milled on Klingelnberg Sferoid machines, module 2 – 10 max. diameter 450 mm.

Pinion shafts:

Max. diameter 250 mm, max. length of 1250 mm, largest possible partition module 16.

LFD: Excellent delivery performance

“The delivery performance of LFD is one of the aspects that I like best. We place framework contracts six months or an entire year in advance. LFD supplies the bearings in its own large warehouse on demand,“ engineer Gerwin Ebbinghaus explains the well-functioning cooperation. In this way, SCHMAHL can work in an order-related manner and call up the necessary batches of bearings exactly according to the production sequence. This is a great advantage as stocking does not have to be performed in the in-house component warehouse.

The measure of all things

The fulfilment of the quality standards is the highest requirement. A certified quality management in accordance with DIN EN ISO 9001:2015 and the continuous qualification of the employees guarantees the highest degree of perfection. Complete documentation of the required material qualities and heat treatment processes are ensured in the in-house materials laboratory. As a leader of measuring technology of the “in process measurements”, the company meets the highest requirements in regard to material, precision and quality./p>