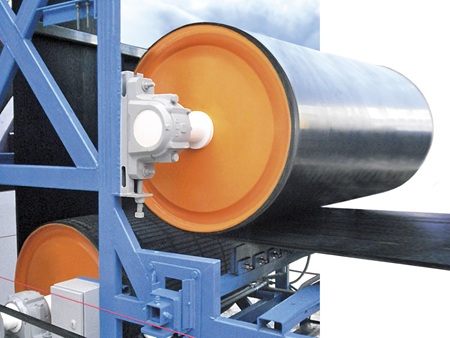

LFD: SNL Bearing housing - A success story

In 2014, LFD developed the modified bearing housings of the SNL design ready for the market and this turned into a success story. Because drives require reliably running rollers.

Crucial further developments

In cooperation with the suppliers, the SNL housing was developed further at critical areas. In this regard, firstly the reinforced construction must be pointed out. Competitors implement savings in the material in order to achieve an even more favourable purchase price. Whereas LFD performed a precise analysis of where the bearing housings are installed and under which loads they are operated. In the course of this, the heat removal was optimized, ensuring that the heat that is generated on the bearing is dissipated into the adjacent construction. This increases the service life of the respective bearings. Here, all common gaskets available on the market can be used. Suitable markings on the housing allow the quick, easy and accurate securing of the SNL housing.

SNL bearing housing by LFD at the very top of the rankings

LFD has performed an internal benchmark test and in the course compared housings from other leading manufacturers with the SNL bearing housing made by LFD. LFD did very well in this comparison. However, now this benchmark has been confirmed by a leading authority. For a customer, for the delivery of cement plants, where the loads truly lie at the limit, the LFD bearing housing was clearly shown to be the best bearing housing. This customer has also performed his own benchmark and compared the bearing housings made by leading manufacturers with the products made by LFD. Here, only the housing made by LFD and one other top brand was able to meet the technical requirements. In the direct comparison between both brands, the LFD bearing housing performed even better. What a result!