LFD QUALITY ASSURANCE

LABORATORY EQUIPMENT AND TEST BENCHES

With its own bearing test benches, which permit test runs of up to 300% of the capacity, the LFD Group ensures a very high quality standard.

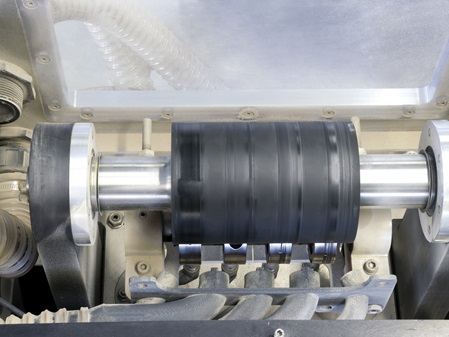

Service life testing

With the test bench WRM 1603, LFD has now, in addition to the already existing test benches, created the possibility of also performing service life testing on small radial bearings. With the variable setting options for rotational speed, force and test temperature, a very wide range of testing conditions can be covered.

Adjustment possibility to real customer applications

In the course of the service life tests, the structure-borne noise values of the bearings are recorded and the test bench is switched off automatically when the set limit values have been reached. The test bench WRM 1603 can be used for the testing of both grease-lubricated enclosed bearings as well as for example open bearings that are operated in the oil sump. Utilising the test temperature that can be adjusted between 40 °C and 80 °C, there is an additional adjustment possibility to real customer applications. Starting with shaft diameters of 8 mm, all bearing types up to a maximum shaft diameter of 30 mm can be tested on the test bench.

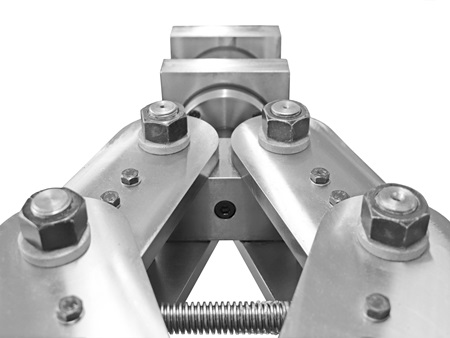

The motor speed can be selected freely between 2,000 rpm and 10,000 rpm and in this manner covers a wide spectrum. Currently, bearing types such as the deep groove ball bearings 608 or 6002, but also 6205, which are installed in sets of four, are in the focus. A special feature of this test bench is in the force application of the radial load.

Radial loads of up to 20,000 N

Radial loads of between 300 N and a maximum of 20,000 N must be applied with the small deep groove ball bearings that are utilised. For this reason, a hydraulic cylinder would be unsuitable for this bandwidth with very low deviations during operation. On the bearing test bench WRM 1603, the precise load of the radial bearings is achieved using a toggle linkage. Using the permanent registration of the force via a load transducer, a step motor adjusts the power of the toggle linkage in a highly precise manner, ensuring that the radial force is kept virtually constant.

Analyses

Comprehensive report files are available during the subsequent bearing analysis, as the current sensor values are stored every two seconds. In addition to the rotational speed, motor output, radial force and temperature, in the recorded structure-borne noise curve additional information is available on the test cycle.

Technical specifications WRM 1603

| Radial load max. | 20.000 N |

| Nominal speed | 2000 rpm |

| Speed max. | 10.000 rpm |

| Motor output | 3,7 KW |

| Operating temperature | 40 - 90 °C |

| Bearing dimension d | 8 - 35 mm |

| Bearing dimension D | 22 - 62 mm |

Dust-dry and wet test

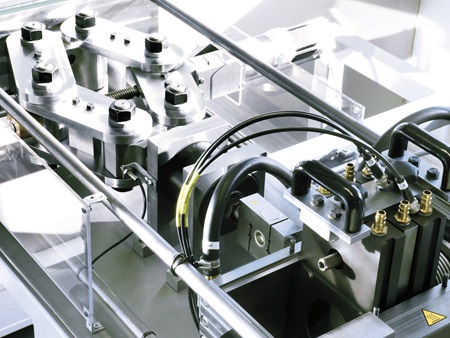

The test bench WSF 1704 has been available since mid-2018 for the further development of the enclosed deep groove ball bearings. The effectiveness of the seals can now be verified in practice in pre-set configurations on environmental influences. Basically, a distinction can be made between dust-dry and wet testing as well as powered inner race or outer ring.

Dust-dry test

During the dust-dry test, a defined amount of “contamination” in the form of foreign particles such as mineral test dust or fine wood chips from a bunker are blown onto the bearings via a pre-portioning.

An optimized air outlet brings the particles directly in the area of the sealing lip. The amount of particles as well as the frequency of the blowing process can be defined freely within limits.

Safeguarding of the efficiency

Wet test

During the wet test, the resistance against the ingress of moisture into the bearing is tested. For this, the variants of atomization, water spray or high pressure are available. Using the different types of water exposure, the corresponding environmental conditions are reproduced for the test bench, e.g. cleaning processes on agricultural equipment.

Mud bath test

A combination of both testing types is performed in the mud bath test. This variant is solely performed with a driven outer ring. All other stated tests can also be performed with a driven inner race.

Analyses

After the end of the test cycle, the effectiveness of the seal is analysed, by for example assessing the amount of particle ingress. Additionally, the documented sensor values are available in a report file for evaluation. Here, for example it can be read out which errors lead to the deactivation of the test cycle.

Technical specifications WSF 1704

| Water spray pressure max. | 3 bar |

| Spray water pressure max. | 10 bar |

| High-pressure cleaner, water pressure max. | 130 bar |

| Nominal speed | 2000 rpm |

| Speed max. | 10.000 rpm |

| Motor output | 3,7 kW |

| Bearing dimension D | 22 - 62 mm |