THIS IS HOW LOGISTICS REALLY STARTS ROLLING

Increasingly diverse goods must be picked individuallyand on-time in the worldwide flow of goods. A trend that requires efficient logistics with economical materials handling systems. Systems, on which bearings at key points safeguard that everything runs smoothly.

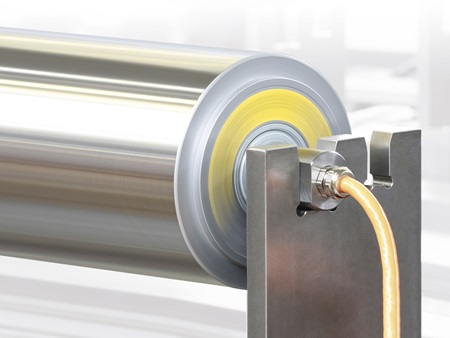

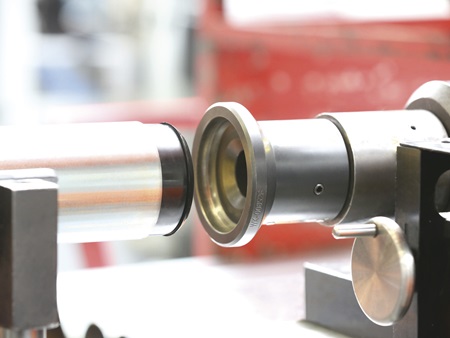

EMQ-Bearings in drum motors

The drum motors made by Interroll serve as efficient drives for conveyor systems and have established themselves with conveyor belts as a simple and compact drive solution. They are mainly developed for the use in belt conveyors and connected conveyor systems and are used in a wide range of sectors.

Interroll systematically relies on high-grade quality of the bearings, as the manufacturer benefits from the reliable service life, the lack of a need for maintenance as well as the robustness of the components. Interroll has tasked an independent institute and a team of bearing experts with the examination and comparison of LFD products. The following was determined: LFD offers high quality that is comparable with the market leaders, however with a considerable price advantage.

Powerful drives for conveyor systems, for example drum motors rely on high-quality bearings.

Optimal degree of efficiency

The drum motors made by Interroll are highly energy-efficient with an overall mechanical efficiency of more than 80%: The output of the electric motor is transferred directly to the conveyor system. This means that the mechanical power loss in comparison with geared motors with a secondary transmission is reduced significantly. Due to the high energy yield and the low power loss, the new motors are considered to be the most energy-efficient conveyor belt system that is currently available in the sector of materials handling.

EMQ bearings are used in the drum motors that have been especially optimized for the electric motor production, as in the chain of the different components always as little friction losses as possible should occur, which would also always result in losses in output. EMQ bearings made by LFD are especially suited for this and minimise possible friction losses.

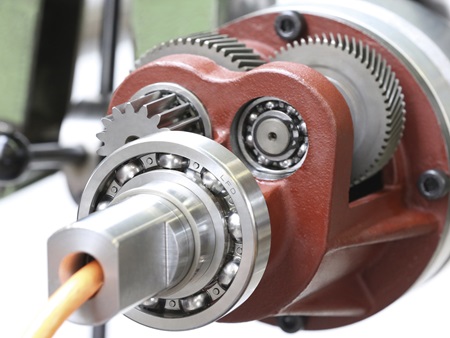

EMQ bearings of the LFD Group

At Interroll, in close cooperation, the gearbox assemblies, the electric motors as well as the bearings are trimmed for low-friction operation. The manufacturer has been able to achieve this successfully in the pairing with the LFD bearings in EMQ quality, as a result of which the products feature a high quality and a long service life. The motor manufacturer is familiar with the verification mechanisms and also appreciates the systems, the test benches and the modern laboratory facilities of the bearing producer based in Dortmund. Regular reports from LFD on the test sequences and also the performance statistics create mutual trust. In turn, Interroll can reinforce the trust with its own customers, as it is not necessary to discuss series faults of the assemblies and it is exactly known what LFD does.

Continuously variable output

When the customer controls the motor using a frequency inverter, then the velocity can be adjusted in a continuously variable manner – an indispensable property when used at supermarket checkouts. This is realised by fitting the soft starter to the conveyor frame.

In this manner, reliable solutions are created for checkout systems, reverse vending machines and the conveyor components connected to these for the return of returnable or recyclable bottles, cans and beverage crates. Interroll drum motors with LFD bearings are also used in distribution centres – even for very heavy loads such as entire pallets. In this manner, the entire supply chain for supermarkets and the retail trade is supplied in a reliable and sustainable manner. When we click on “buy” on the Internet, precisely these motors, rollers and bearings ensure the quick delivery of the ordered goods. The rollers are also manufactured completely in-house. However, in this regard, Interroll has a core competency in the development of such high-performance thermoplastic materials in its own injection moulding plant in Switzerland.

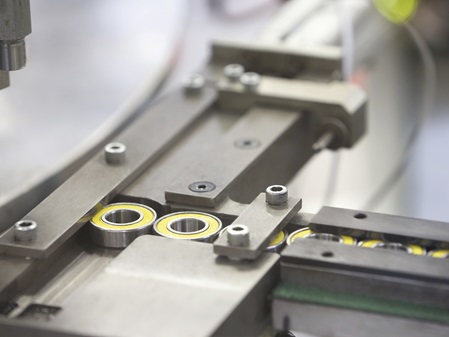

LFD ensures high quality

At Interroll solutions, the ball bearings delivered by LFD are pressed directly into the powerful rollers. The fit is precise down to a tenth of a millimetre. The production processes are safeguarded in such a manner that the bearings are always pressed in at exactly the same position. In this manner, a high degree of quality can be ensured.

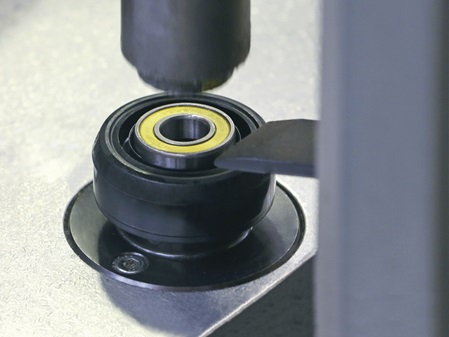

Higher chrome content in the bearing steel

Specific and also very different requirements are set to machines that facilitate the automated processing of foods. Due to its own fully automated manufacture of deep groove ball bearings with quality management in accordance with German standards, LFD has been a partner of roller and drum motor manufacturers for many years. When the installed bearings do not run in a fully encapsulated manner, then they must be made of stainless and acid-resistant steels. Only in this manner will they on the one hand be corrosion-inhibiting and able to resist the intensive water jet or steam cleaning processes and on the other hand acid resistant towards the very aggressive cleaning agents that are utilised.

LFD complies with such stringent requirements with the increase of the chrome content and in this manner will significantly improve the corrosion inhibiting properties. For example, the utilised corrosion-inhibiting steel features a chrome content of around 17% and is well suited for the use as a bearing steel, as it can achieve values of 58 HRC when it is hardened.

Strict requirements for hygiene apply in all areas of the food industry involving the direct contact with the goods. As a result, here only foodstuff-approved lubricants according to the American standard USHD-H1 are used, while in the event of the use of bearings with sealed housings, grease types of the sub-standard H2 may be used. LFD solely works with brand greases, which have already successfully proven their properties under these special operating conditions. Simultaneously, LFD bearings are used here with a specific inner race design and an application-optimized groove, which additionally prevents the direct ingress of water and cleaning agents as a result of the labyrinth effect. As one of the worldwide leading manufacturers in the internal logistics, Interroll has created a conveyor drive that currently is the most hygienic available on the market. The company additionally uses the reliable LFD bearings, which also meet the requirements set in this regard.

LFD-EMQ-Bearings

OPTIMIZED FOR ELECTRIC MOTORS

EMQ bearings (“Electric Motor Quality”) are bearings that have been specifically optimized for use in electric motors. In these bearings, internal maximum requirements are set in regard to quality, however, additionally, our own modifications necessary for the specific application have also been implemented. Among others, the results are also reflected in the required low noise emissions of the EMQ bearings.